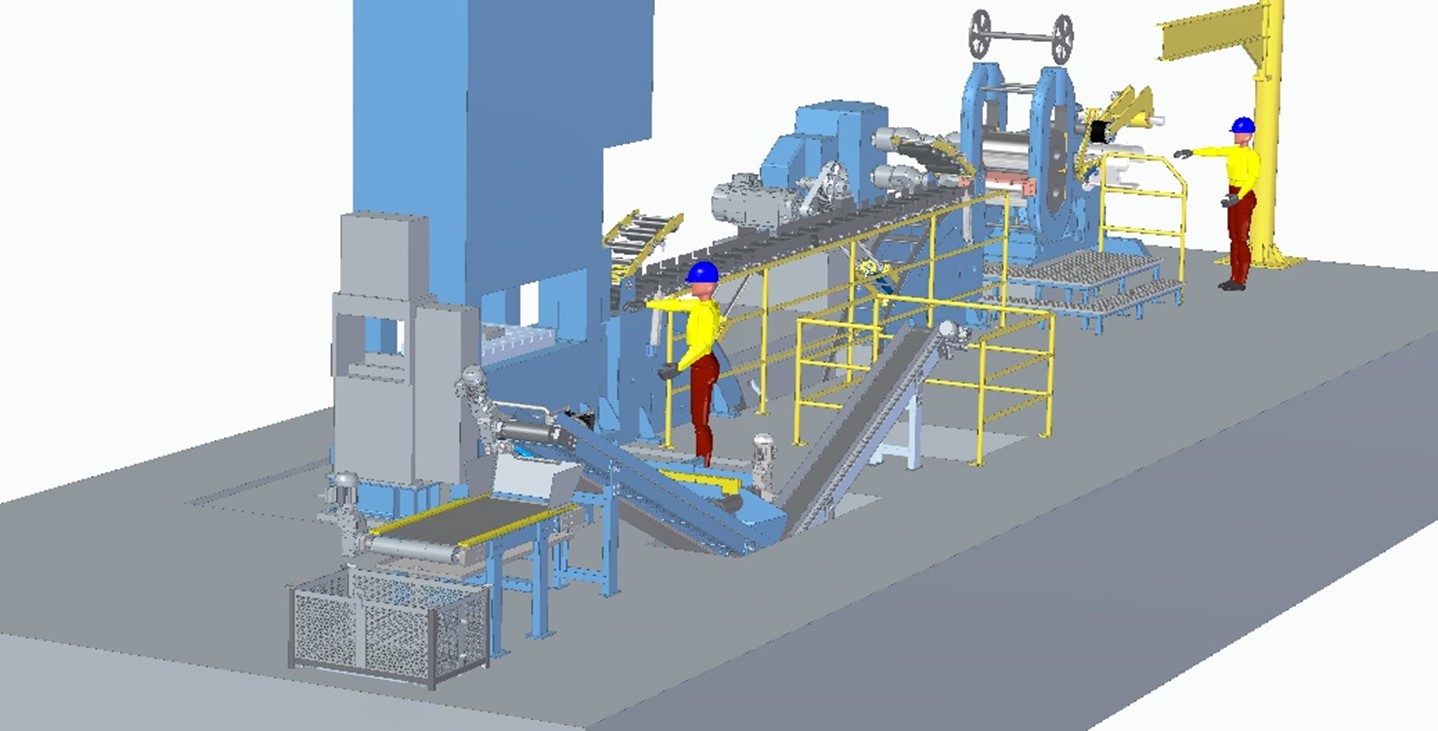

Die press line – renovation and modernization

We were taking part in the renovation and manufacture of machinery in the die cutting line of roundels. We renewed the gear and the older rolling mill. We manufactured the unwinding unit with the aluminum sheet, the inlet unit with roller tables in front of the rolling mill, and the bridge table for aluminum sheet. The project also included belt conveyors for the cut out roundels.

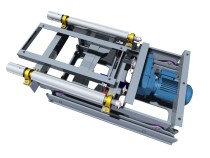

Machine for sawing and chamfering of billets

The machine serves for the automated double sided sawing to the desired measure and for the chamfering of edges of the round aluminum billets with the diameter from Ø 7 to Ø 70 mm and the length up to 6 m. The saw is composed of the feeding unit for the collection of billets, transport unit, conveying the billets to the place of sawing, bed lengths, and of the sawing and the chamfering unit. The machine equipment also comprises the transporter and the chip suction unit.

Automated aluminum billet storage

The storage serves for the storage of the cast aluminum billets. One row comprises approximately 105 storing places for 1,050.00 billets, which amount to almost 1,500.00 tons of stored material. The storage plant is completely automated. The lifting manipulators (two per line) supply the storing places from the conveying point at the homogenization process to the transportation of billets to the outlet chain ramp, from where the material continues its route to other process premises at distant sites. Such method of storing significantly reduces the required surface, intended for the interim storing, and in addition to this, the stocks and records of different material alloys are computerized.

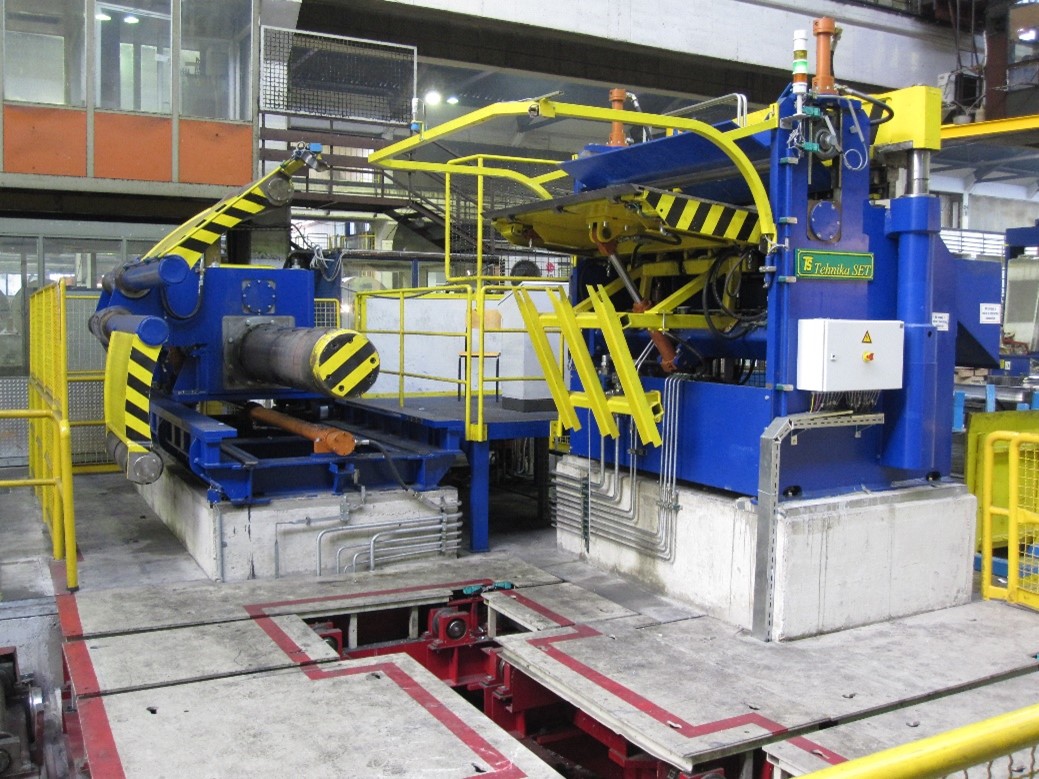

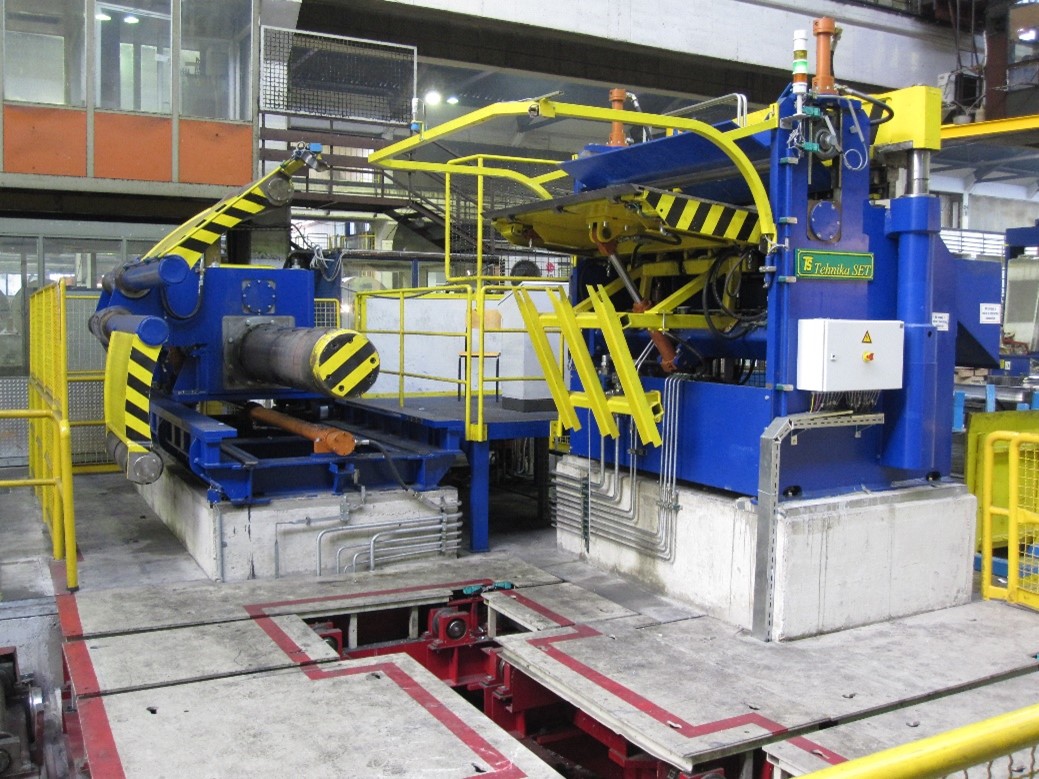

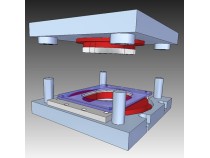

Coil preparation station

The starting part of the aluminum, wound to the coil, is usually damaged and not suitable for further processing. The cutting off of these scrap parts is carried out by the machine, intended for the preliminary treatment of a coil, which continues, later on, its route to the rolling mill. The equipment is composed of a lifting device, conveying the coil (12 tons) to the unwinder, the inlet unit with a roller table, sheet gripper, sheet shears, and a scrap manipulator. The unwinder, as well as the roller table, are driven by means of the electric motor and the reduction gear, while the shears and the inlet table are hydraulically driven. The device is also equipped by the control panel and the operator’s platform.

Billet depalletizer

The device serves for the automated emptying of pallets with short billets, intended for further processing. It is composed of a short pallet conveyor with the manipulator, which grips the bars from the pallet and loads them to the short roller line. The reloading system transfers the bars from one line to the other. Then, the empty pallet is conveyed to the depositing place, from where it is returned back by the forklift to the loading place.

_r.jpg)

_r.jpg)

_r.jpg)

_r.jpg)

CALL US TO: +386 2 8453 250

CALL US TO: +386 2 8453 250